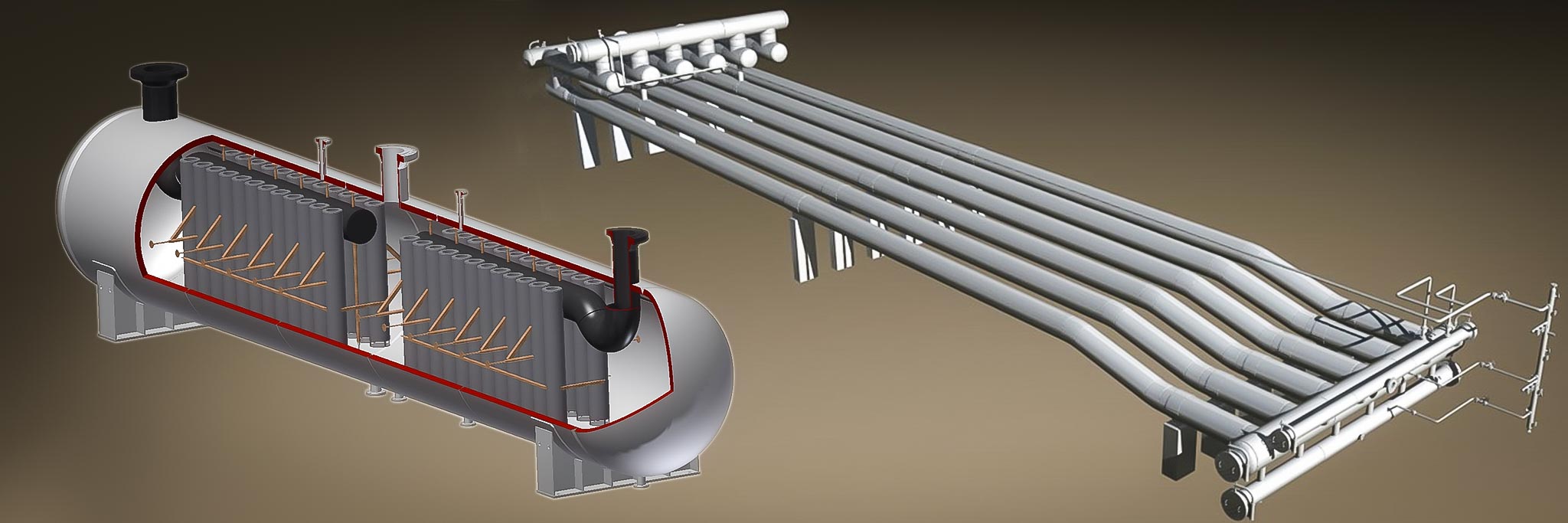

You know you need a slug catcher but you aren’t sure if you need a vessel or a finger type. Using the 5 metrics below, you’ll be able to quickly identify the direction you should consider.

1. Storage Capacity or Size of your Slug

- 500 bbls or less: Vertical L-Type, B31.8, single or multi-tube. 500 micron separation performance.

- 1200-1500 bbls or less: Vessel Type, ASME Section VIII, Div 1 or 2. 150 micron separation performance.

- 1200-1500 bbls or more: Finger type (Harp Type, Pipe Type), B31.8 or B31.1. 150 micron separation performance. This is the most economical way to receive and store large slugs.

2. Plot Space

- In general, finger slug catchers are going to be longer than vessel slug catchers.

- Finger type slug catchers are most economical when they are long and skinny (minimize the number of fingers to process only the required gas flow rate). If your allotted plot space is very short (<100ft), it is likely that a vessel or vessels will be more economical.

- At >1500bbls, the vessel design will be wider and require more inlet piping than the finger type design.

- At >1500bbls, and unlimited plot space, finger type slug catchers will be more economical. Extrusions help limit the plot space and # of weld joints as compared to tees.

3. Lead Time

- A standard vessel slug catcher (say 500 bbls), is 36-42 weeks. A custom project that requires multiple vessels could take as long as 42-48 weeks.

- A standard finger or harp slug catcher can be delivered in 18-24 weeks with custom jobs needing 34-48 weeks.

4. Delivery

- Depending on your location, freight for you slug catcher can be very costly (especially for vessels).

- A finger slug catcher is typically shipped in 2-4 modules plus all the storage line pipe to the field. Freight is relatively inexpensive and easy to find no matter the location.

- Large vessels can cost just as much to ship as they are to build, especially in the Marcellus, Canadian, and Rocky Mountain regions. This is less of a concern in West Texas. Be sure to get a budget once you know the size of your vessel.

- In some Latin or South American countries, a finger type may be the only design that can be safely shipped on the highway system.

5. Field Install – Skilled Labor Availability

- Finger type slug catchers require a significant amount of site welding and labor. While no pieces will require the crane capacity of a vessel, you will need to set numerous sticks of pipe and also provide numerous field welds. In some parts of the US and foreign countries, skilled welders can be hard to find. In these locations, you may want to avoid finger slug catchers.

- Installation of a vessel slug catcher will be fairly simple and straightforward. There is minimal welding and the time to install is shorter (of course offset by longer fabrication times). The rigging and large foundation costs can mount when you have >2 vessels.

- Be aware, once the need for more than 2 vessel slug catchers is required, it’s probably worth comparing a finger type and to a vessel.

BONUS! Cost/Delivery Evaluation

Pressure Vessel

- Cost: $3.50 – $4.00 / lb.

- Delivery: 30 – 52 weeks

Harp Style

- Line Pipe cost: $1.00 USD / lb.

- Extruded Manifolds: $7.00 USD / lb.

- Delivery: 18 – 38 weeks

So you’re on a budget? Check out these 5 tips to save money on your next Slug Catcher Project.

As a leader in Slug Catcher design, here are some guidelines every engineer should know.

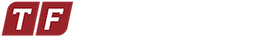

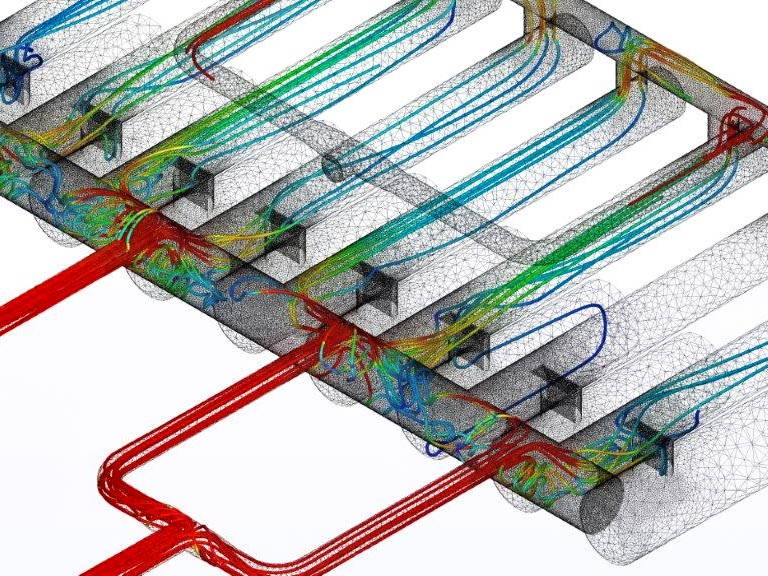

Even distribution is critical for proper operation of finger type slug catchers.

Understanding the separation methods for your finger-type slug catcher.

WHY US

Taylor Forge Engineered Systems

has continued the reputation of traditionally dependable products

to a variety of industries.

Integrity

We don’t compromise our practices and we won’t cut corners.