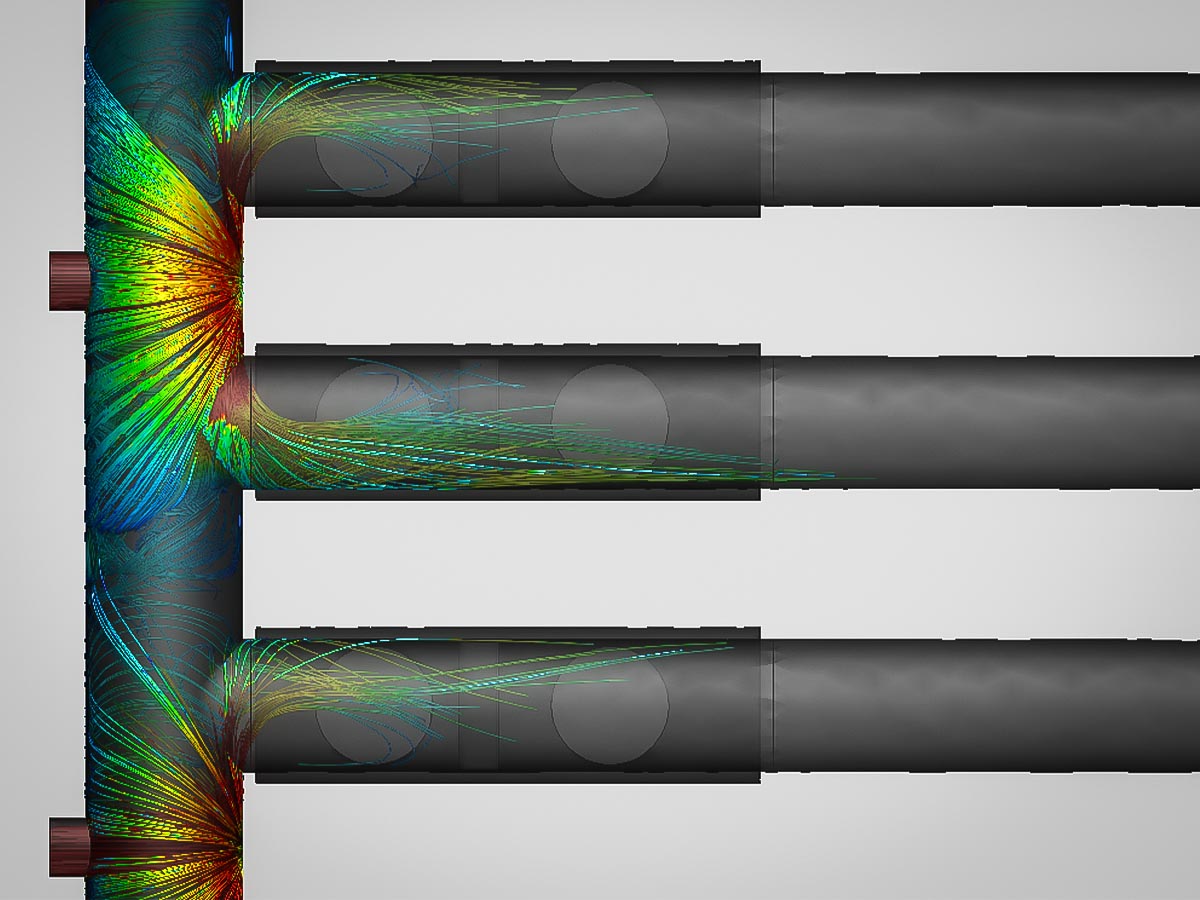

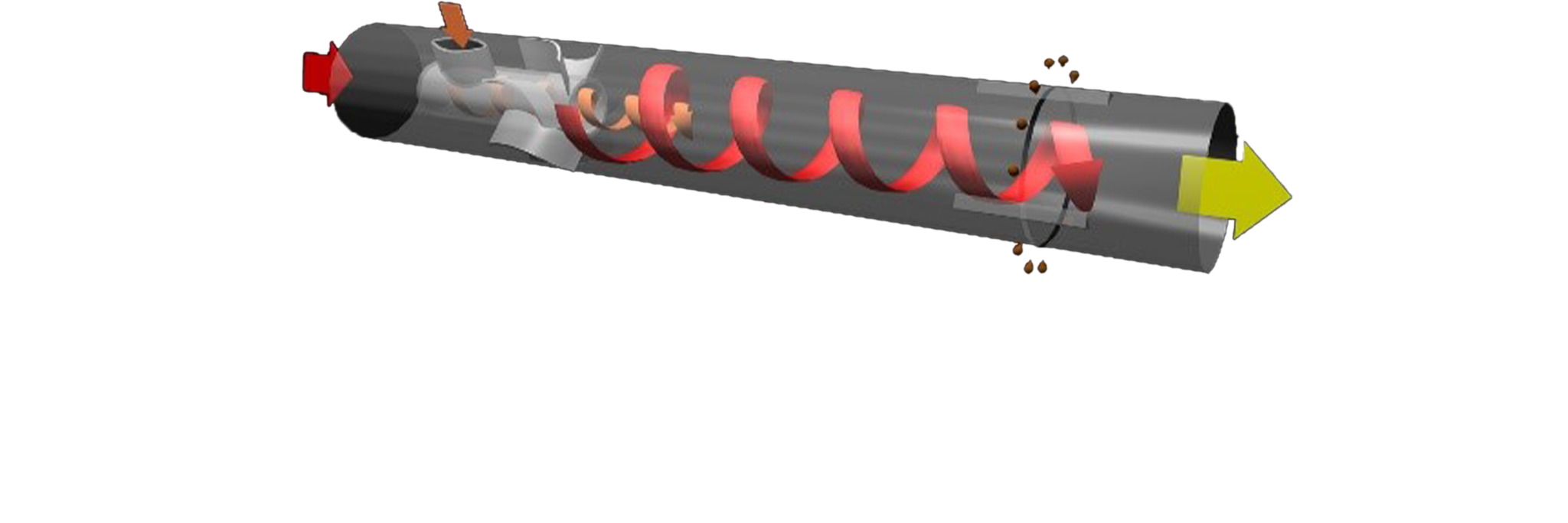

Vortex Tube Design

Taylor Forge offers two Vortex Tube configurations which are used in horizontal and vertical 2 phase separation Vortex Tube separators or scrubbers will provide at optimum conditions, efficiency of 99.9% removal of solids and free liquids down to 1 micron.

Vortex Tube separators / scrubbers will remove free liquids and solids from the inlet gas using an Axial Flow Vortex Tube. These tubes range from 2” O.D. to 8” O.D. and could be installed as either one tube or multiple tubes based upon flow rate. Vortex Tube separators are the perfect scrubber in front or behind compressors, dehy’s., Fuel Gas Scrubbers, etc..

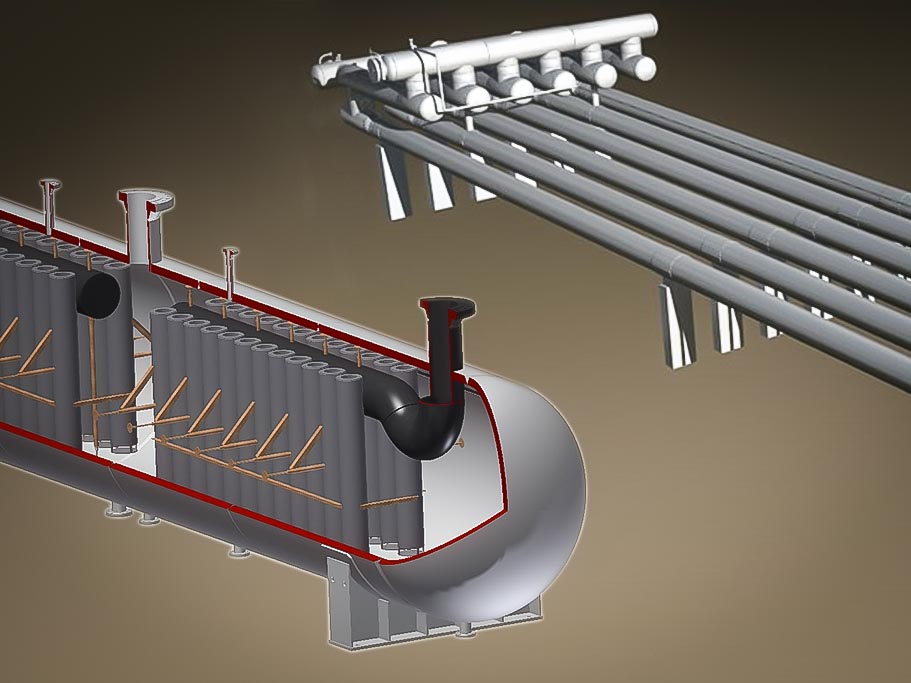

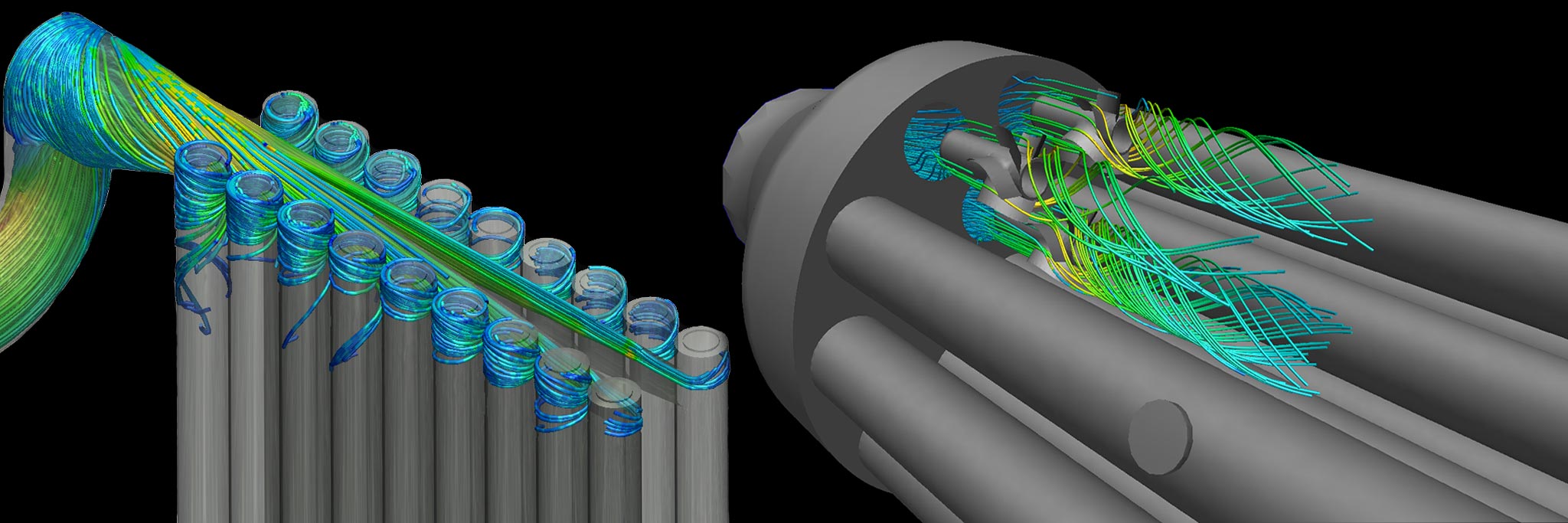

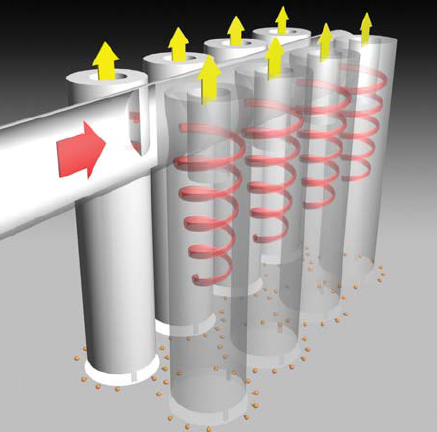

Vortex Cluster Design

Vortex Clusters are used in new or existing vessels in 2 or 3 phase separation of liquid, gas, solid, or combinational flows. The cluster alignment is more effective when used to achieve high efficiency separation while also removing large bulk liquids, ex: slug catchers.

By increasing throughput efficiency and decreasing residence time vortex is capable of drastically reducing the size of otherwise conventional separation vessels and systems. In retrofit applications, Taylor Forge is able to fabricate vortex internals to install in the existing vessel to increase efficiencies and handle increased production without the need for additional equipment.

What does it take to decide if vortex is right for my application? At Taylor Forge our design considerations are thorough and customizable for each specific job. Before sizing vortex tubes or clusters we begin with the operating pressure (psig) and gas flow (MMscfd). Fluid composition is also required for adequate design which include gas, oil, and water compositions, as well as phase characteristics such as mist, foam, and emulsion. Along with calculating the size of the vortex tubes and clusters, obtaining these parameters also assists with our design and placement of the vortex equipment relative to the corresponding liquid interface levels.

So you’re on a budget? Check out these 5 tips to save money on your next Slug Catcher Project.

Choosing the type of Slug Catcher equipment for your next project? This breakdown will help guide your decision.

Understanding the separation methods for your finger-type slug catcher.

WHY US

Taylor Forge Engineered Systems

has continued the reputation of traditionally dependable products

to a variety of industries.

Integrity

We don’t compromise our practices and we won’t cut corners.